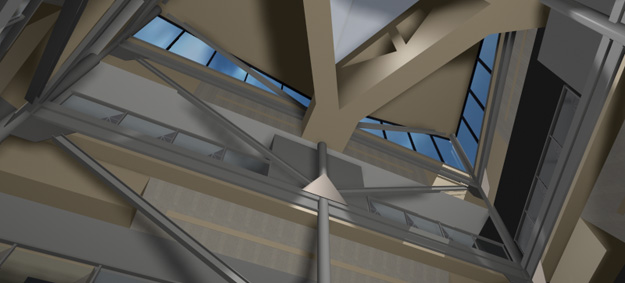

Project Specifications

the design technical resource consultant....

"Design Oriented Architectural & Engineering firms" want to work with.

Let our firm bring added value to your team...

architectural services for nearly

$6.8 billion in construction projects.

Thomas Berger, Managing Principal

l

We have Written Thousands of General & Technical Specification Sections

Our Specifications are based upon actual Construction Experience

Our Specifications are Continually Updated to Reflect Technology Advances

Our Specifications Define & Protect your Design Intent

Construction Specifications

Advantages

We have extensive experience in developing technical building specifications that comes with hundreds of projects, billions of dollars in construction costs, multiple offices, technical and support staff, along with some of the best resources in the country all in one firm.

Ten years ago we developed the studio approach to providing our clients with the best technical services in the west. We have employed staff from various backgrounds and experience and created an environment which allows us to learn for our experiences, both old and new. Our technical staff are exposed in one year to the experience that a typical Architect would be exposed to in six to seven years. With many of us working on as many as 30 projects a year, from high rises to courthouses, city halls, libraries, mixed-use projects, police stations, research labs, military facilities, universities to private & public education, hospitality projects and large scale retail… we have a lot knowledge to share.

Our Approach

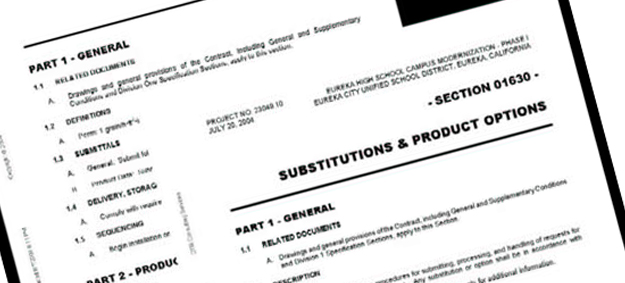

At DTR, we feel Specifications should never be written naming a product only followed by "or equal..." This will create more work for the Architect/Engineer in the Construction Phase, needlessly exhausting your limited resources. Why we say this is that as much as 50 percent of other manufacturers will submit their product in lieu of what was specified as a substitution request.

On a public jobs, where no descriptive or performance data was included in the bid specifications, the Architect or Designer must individually obtain current product cut sheets on both the product specified and the substituted product and begin the sometimes laborious task of determining whether the product meets or exceeds the specified product. With some products or systems this may take anywhere from an hour, to several hours or even a day to review more complex systems. Multiply that times hundreds of potentially substituted products equals thousands of lost revenue for your team.

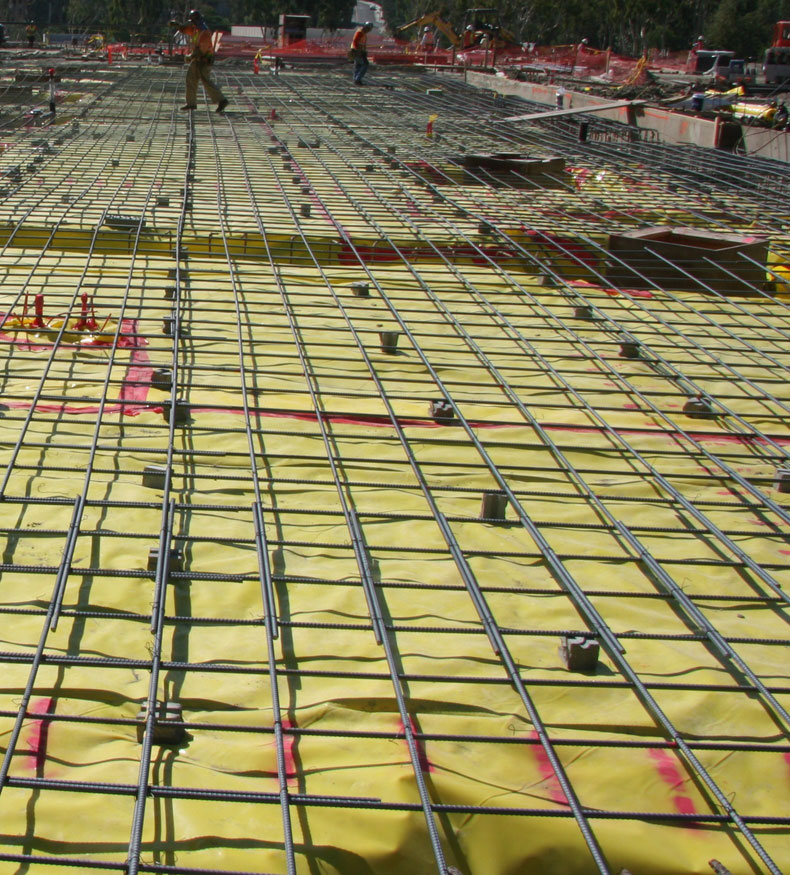

DTR will work with you and your firm to specify products in both a descriptive and performance based open proprietary specification where performance and esthetics are important.

Project Manual

Specifications are written to communicate with potentially hundreds of people involved with the project, to assure they implement both the intent of the designers and the requirements needed to assure proper installation. Specifications can be as complex to develop as the construction drawings and can range from a single printed volume to several volumes. In some respects, this work is similar to that of an attorney producing a contract.

DTR Consulting Services uses both the 16-division 1995 MasterFormat & the 50-division 2004/2010 MasterFormat system of information organization developed and improved over the years by members of The Construction Specifications Institute (CSI). These divisions cover the various materials, products, and equipment that go into a building. They are important because they govern the way information is filed in the design office library, and they assure consistency among construction documents nationwide.

Each project specification section describes a unit of work and end product. Specification sections are broken down into three basics parts under the CSI SectionFormat as follows:

Part 1 - General Summerizes work covered in Section, covers applicable industry standards, references to other sections or documents, defines LEED requirements, governs specific submittals, establishes quality asssurance, lists specific code or testing references, describes mock-ups, notes specific site conditions, may list performance criteria, special warranties and required maintenance services.

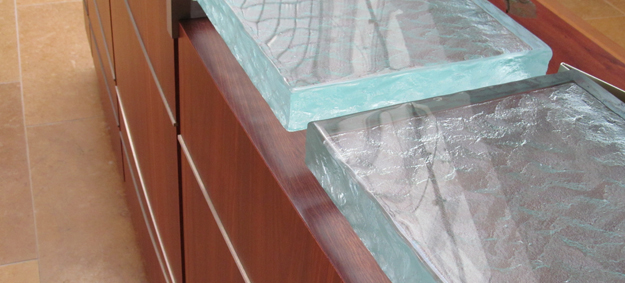

Part 2 - Products Describes products and assemblies to be used on the project, names of acceptable manufacturers, product accessories, material desciptions & performance data, fabrication requirements, finishes and other product performance criteria.

Part 3 - Execution Addresses substrate preparation, examination, installation requirements for products and accessories, processes and job site conditions that must be maintained during product usage including field quality assurance testing, cleaning and protection of finished products.

Types of Specifications

Specifications may be written in multiple acceptable ways, but are usually written as a combination of the following:

Performance Specifications: Specifications describe the product without mentioning the manufacturer. Requirements might include meeting a specific wind load, color range, or structural loading. These types of specifications required results with the criteria to verifying compliance without unnecessary limiting the method of achieving those results. Examples might be specifications for fabricated exit stairway or fire resistant joint sealants. Simply stated, the specifications specify an end result.

Descriptive Specifications: Specification formed as a detailed written description of the required properties of a product, materials, or equipment and the workmanship required for its proper installation. They define exact properties of materials and methods of installation without using proprietary product names.

Prescriptive Specifications: A prescriptive specification is one that includes clauses for means and methods of construction and composition of the concrete mix or a traditional plaster mix rather than defining performance requirements.

Reference Specifications: These specifications refer to an authority, trade association, government or other industry reference standards; provide a generic description in terms of an assembly meeting those standards, such as ASTM, TCNA, ANSI, etc.

Proprietary Specifications: There are both Closed and Open versions of the Proprietary specifications defined as follows:

Closed: Only one Product is named and no substitutions would be accepted.

Open: One product may be named as a basis of design, with multiple other products named as acceptable products or list the proprietary brand names of one or more manufacturers. Substitutions would be allowed and would be processed through the General Requirements (Division 01) substitution procedures.